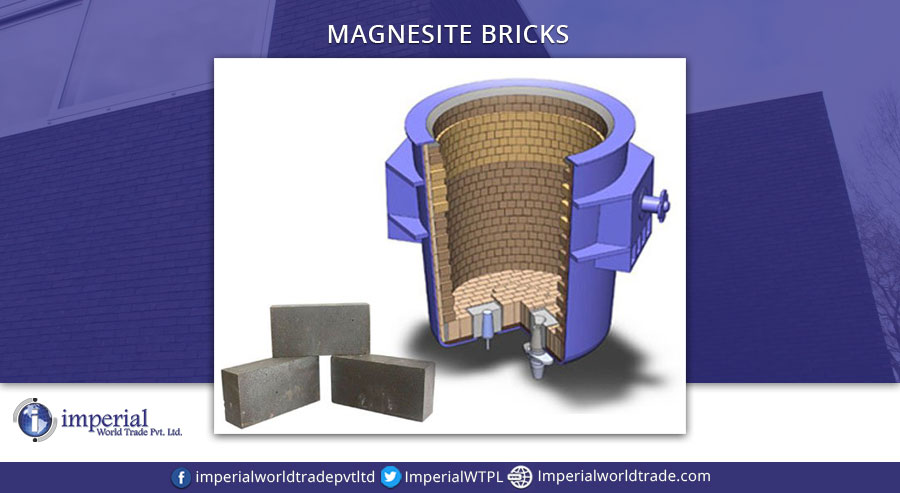

If you are looking for one of the best basic refractory bricks; then Magnesite Bricks is one of the first and foremost choices you can trust on. These kinds of bricks are usually produced in various qualities depending upon g the grade of magnesites being used in.

With the increasing competition in the market; a large number of Magnesite bricks manufacturers have got involved in the market now so that the customers can purchase high-quality refractory products at the affordable price range.

Most of the Magnesite Bricks manufacturers produce these bricks as per the customer’s requests, process conditions and applications along with taking refractoriness, chemical corrosion resistance, flexibility, thermal conductivity and coating abilities in consideration.

Magnesite bricks suppliers are bound to provide you a large variety of best quality magnesite bricks. One of the most common reasons for having a huge demand for these kinds of bricks is the high strength, purity and fine finish.

These bricks are usually formed by using optimum quality raw material and cutting-edge technology as per industry norms. You can easily get these bricks in different designs and dimensions so that to add a perfect touch to your construction site.

Features of Magnesite Bricks

– Magnesite bricks come up with a variety of options and affordable price tags which makes it a one of the most popular demanded options in the market.

– These are the high strength bricks which include elegant look which easily attract a large number of vendors towards it.

– The durability of magnesite bricks is one of another feature which makes it popular among the users.

Types of Magnesite bricks

Magnesite bricks are common of two types:

Burned Magnesite Bricks:

These types of Magnesite bricks use magnesia as raw material. The burned magnesite bricks are perfectly designed and developed to bear high temperature and strong slag resistance and hence perfect to be used in places which need to have faced a very high temperature usually such as permanent linings of EAF and stell convertors, lime kilns, glass tank regenerators torpedo cars and non-ferrous furnaces etc.

Fused Magnesite Bricks:

These are the kinds of bricks which are made up of fused magnesia which is shaped under high pressure, and fired under ultra-high temperature along with post technical treatment so that the customers could have perfect bricks with perfect finishing.

These bricks include high bulk density and also are perfectly designed and developed to bear high temperature and strong hydration resistance. You can easily use these bricks in tapping holes of converters, slag line of non-ferrous furnaces, tapping holes of metal mixer furnaces and chimney blocks of glass tank refrigerators etc.